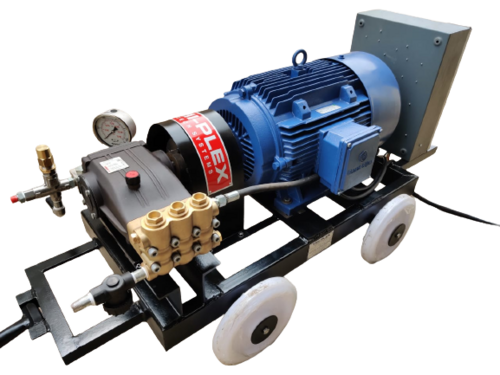

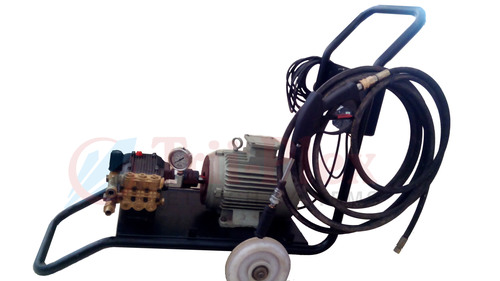

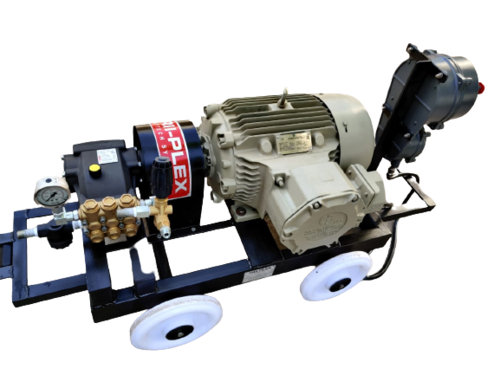

High Pressure Water Jetting Machine

Product Details:

- Theory Reciprocating Pump

- Flow Rate 15 LPM, 250 BAR

- Material High Strength

- Structure Piston Pump

- Power Electric Watt (w)

- Pressure High Pressure Bar

- Click to View more

High Pressure Water Jetting Machine Price And Quantity

- 130000.00 INR/Unit

- 1 Unit

High Pressure Water Jetting Machine Product Specifications

- Piston Pump

- Electric Watt (w)

- Reciprocating Pump

- High Pressure Bar

- 15 LPM, 250 BAR

- High Strength

High Pressure Water Jetting Machine Trade Information

- Mumbai, Mundra, Pipavav, Kandla, Other Port

- 50 Unit Per Week

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden Boxes with Bubble Plastic Wrapping, Export packaging and As per client requirement.

- All India

- CST, VAT, IEC Certificate available, Pump Testing after give it to customer.

Product Description

Trii-plex Jettech Systems are Manufacturers of High Pressure Water Jetting Machine as per client requirement of Flow Rate & Pressure. The offered Triplex Plunger Pump is manufactured using supreme grade components by our skilled professionals at modern production unit. In addition to this, the provided Water Jet Cleaner Pump can be bought from us at reasonable rates.

Key Points: Sturdiness, Less maintenance, Optimum strength, Defect free

Technical Specification:

Model No: NPM-15.250

Flow Rate: 15 LPM (3.96 GPM)

Min. Pressure: 180 BAR (2610 PSI)

Max. Pressure: 250 BAR (3600 PSI)

Motor (HP): 7.5HP 10HP (Standard / Flameproof)

Technical Features about Plunger Pump:

Pump Head: Forged Brass.

Plungers: Solid Ceramic Plungers.

Pump Main Body: Fully anodized Crankcase.

Connecting Rod: High wear resistant Forged Alloy Steel.

Crank Shaft: High wear resistant Forged Alloy Steel.

Plunger Seal: Improved low and high pressure seals.

Valve Assembly: High wear resistant Stainless Steel.

Oil: 15W40.

Major Cleaning Applications of High Pressure Jet Machine includes:

Cleaning after pickling in steel industry

Hydro Pressure Test

Parking Area Cleaning

Solar Panel Cleaning

Heavy Vehicle, Car Wash Cleaning

Casting cleaning

Tank cleaning

Vessel cleaning

Live wire insulator washing

Ship hull cleaning

Concrete and brick cleaning

Sewer cleaning

De-burring molded parts

Utensil cleaning

Cleaning of concrete mixers

Felt & wire screen cleaning

Machinery cleaning

Paper machine cleaning

Pressure cleaning in poultry farms

Accessories we supply with systems:

01. Plunger Bare Pump (HAWK Make)

02. Electric Motor (Three Phase Standard / Flameproof)

03. Platform (Base frame / Trolley mounted)

04. Pressure Gauge

05. Unloader Valve (Pressure Relief Valve)

06. DOL Starter / Control Panel

07. Suction Filter

08. Trigger Operated Gun (Without Trigger available)

09. High Pressure Suction Hose 10 Mtrs

10. Low Pressure Bypass hose

11. Cleaning Nozzles

12. Rigid Lances 400mm, 600mm, 800mm, 1000mm

Advantage of Pressure Water cleaning machine

1, Low cost

2, washing Result is good

3, washing speed is fast

4, High Price Quality Ratio

5, Environment friendly

6, Wide Application Range

Our Services:

1. Prompt reply, clear communication and quick feedback

2. Comprehensive consultation services, sophisticated solutions

3. Experienced engineers and specialists technical support

4. Customized one-to-one real condition and proposal design

5. Warranty: 12 months, expect for quick-wear part

6. Well-stocked spare parts for replacement and maintenance

7. Sustaining post-sale tracking service

BENEFITS

High-Pressure Jet Machine directs Water Jet at High Pressure against a surface to clean, descale, degrease or prepare a surface. Pressure Jet Washer Cleaners may use Cold Water to perform their function, or mixed with various cleansers, detergents or solvents. They are used for surface Cleaning, or for the demolition of products made of metal, wood, concrete, stone, plastic, glass, Paint removal or other building materials.

Other Products in 'Water Jet Cleaner Pumps' category

|

TRII-PLEX JETTECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |