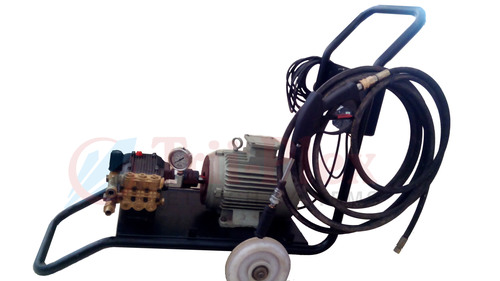

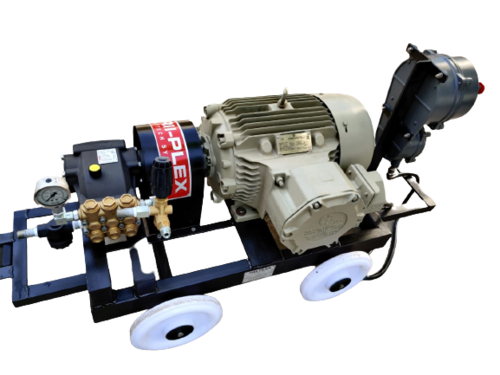

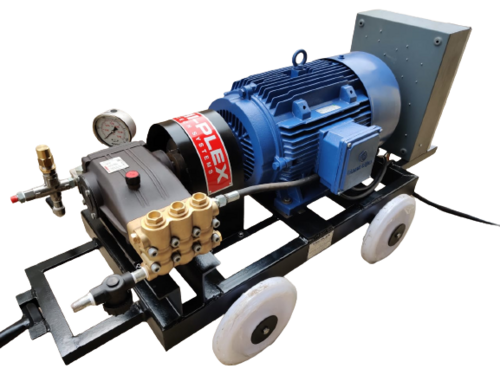

Industrial Cleaning Pump

Product Details:

- Usage Industrial

- Max Suction 17 LPM

- Flow Rate 17 LPM

- Size Different Available

- Product Type Industrial Plunger Pump

- Color Black

- Theory Jet Pump

- Click to View more

Industrial Cleaning Pump Price And Quantity

- 175000 INR/Unit

- 1 Unit

Industrial Cleaning Pump Product Specifications

- High Pressure Bar

- 17 LPM

- 17 LPM

- Industrial

- Size

- Jet Pump

- Electric Watt (w)

- High Strength

- Piston Pump

- Positive

- Black

- Industrial Plunger Pump

- Different Available

Industrial Cleaning Pump Trade Information

- Mumbai, Mundra, Kandla, Pipavav Port

- Telegraphic Transfer (T/T) Western Union Cash Against Delivery (CAD)

- 50 Unit Per Week

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden box with plastic wrapping, Export packaging, As per customer requirement

- Asia Middle East Eastern Europe Africa

- All India

Product Description

Electric Hydro Pressure Testing Pump Equipment are Characteristic capability to perform Hydrostatic Test of Tubes, Pipes, Hoses, Cylinder, Hydro testing of Pressure Vessels & Boilers, Hydrostatic Test Pump of Cross Country Pipe Lines, Valves, Castings, Components, etc. for Leaks, Cracks or Defects.

Trii-plex Jettech Systems are Manufacturers; Suppliers & Exporters of Hydrostatic Pressure Testing Pump 17 LPM and Pressure 350 BAR with Electric Driven & Diesel Driven.

Every Pressure Test is different and that is why the solutions of our Trii-plex Jettech Systems engineers are as diverse as your applications. For with our extensive expertise we can adapt every Test Pump to your specific needs. Pressure and Flow Rates can be individually set and controlled and the pressure testing progression can be clearly logged. With Hydrostatic Testing, component or vessel is tested with a liquid (typically water), and pressurizing until test pressure is reached. Once the pressure is reached, the test is complete, and for other tests hydrostatic pressure must be held for a specific amount of time. Depending on the application, the hydrostatic testing can be used to help identify leaks, structural integrity, manufacturing flaws, wear, corrosion and burst pressure.

Technical Specification:

- Model No: PXI17.350

- Flow Rate: 17 LPM (4.49 GPM)

- Min. Pressure: 275 BAR (4000 PSI)

- Max. Pressure: 350 BAR (5000 PSI)

- Motor(HP): 12.5HP 15HP (Standard / Flameproof)

Technical Features about Plunger Pump:

- Pump Head: Forged Brass.

- Plungers: Solid Ceramic Plungers.

- Pump Main Body: Fully anodized Crankcase.

- Connecting Rod: High wear resistant Forged Alloy Steel.

- Crank Shaft: High wear resistant Forged Alloy Steel.

- Plunger Seal: Improved low and high pressure seals.

- Valve Assembly: High wear resistant Stainless Steel.

- Oil: 15W40

Features:

- Robust Construction

- Low and Easy Maintenance

- Simple and Comfortable Design

- Easy Installation

- Volumetric Efficiency 95% (maximum)

- Extra Heavy duty Power Frame ensures uninterrupted smooth long life

- Easy to maintain, simple to repair & nominal maintenance needed in case of breakdown

Applications:

- Cross Country Pipelines

- Pressure Vessels

- C.I. Mains

- Casting Parts

- Boilers

- Gas Cylinders

- Pipes & Tube Parts

- Fire Extinguisher

Special Features:

Electrically Motorized Driven System, Quick Acting Relief valve, Totally Dependable, Reliable and Efficient Performance.

Standard Accessories:

- Pressure Release Valve made from Brass Metal.

- Discharge Pressure Hose with Attachment o" BSP Length 10 Mtrs.

- Stainless Steel Glycerin filled Pressure Gauge with 4" Dial.

- Suction & Discharge valve (NRV) Made from Stainless steel Material.

- Pressure Set Valve Made from Stainless Steel.

Optional Accessories:

- Automation Control Panel

- Water Tank with water capacity of 50 liters

- Trolley Mounted

Other Products in 'Water Jet Cleaner Pumps' category

|

TRII-PLEX JETTECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |